System Integration

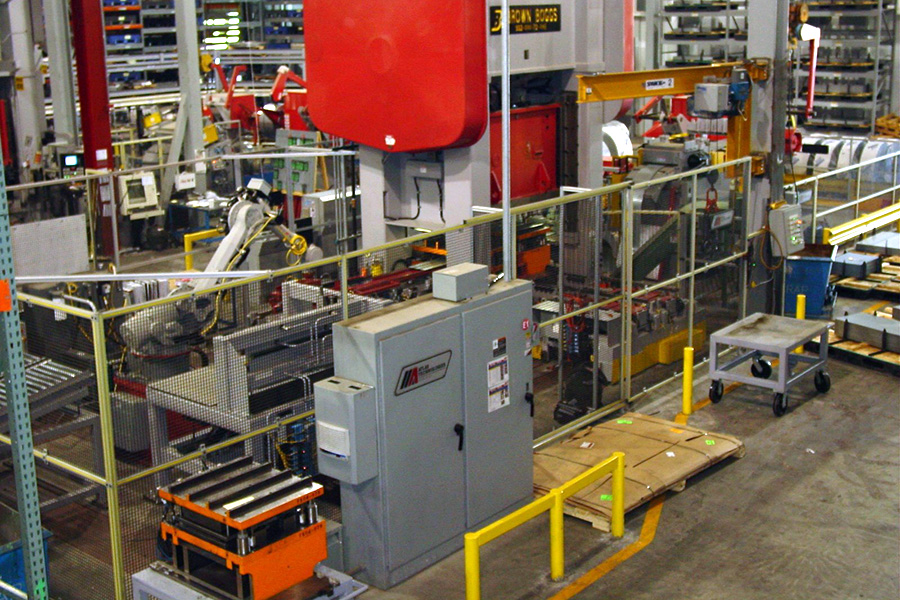

Atlas Systems Integrations are designed and built from concept to production. Atlas will turn a new or used press into a multi-function stamping cell, or we can design and build an integrated fabrication and assembly system from the ground up. Our 50 years of metal forming expertise will turn your manufacturing demands into manufacturing solutions through System Integration!

System Integration: Expertise

Atlas has experience with almost every type of sheet metal automation that is used in System Integration including:

- Blanking and blank handling including stacking, reorientation, coating and washing.

- Press-to-press and in-press part transfer automation.

- Panel processing including notching, bending, piercing, welding and palletizing processes.

- Assembly and welding cells for fabricated parts.

- Finished part handling to include racking, and end of line.

- Automatic storage and retrieval systems for dies and materials.

- Optimizing die design for automation processes.

- Objective based engineering studies to determine the optimum blend of manual operations, automation and controls.

- Turnkey responsibilities to include facilities upgrades or additions along with the manufacturing system.

- Long term production support.

System Integration: Products

The Atlas team is well equipped to handle System Integration projects from full Turn-Key Systems designs to installation and start-up. The following is a small sampling of the numerous variations of System Integrations that Atlas Technologies can design for you:

- Atlas designed and integrated a complete automatic die storage and retrieval system that serves two presses for an appliance manufacturing facility.

- Atlas assisted with the integration and installation of a complete louvered panel line system for a major HVAC manufacturer.

- Atlas designed, built and installed four FLEX Transfer Press Cells within a large contract stamping facility.

- Atlas reconfigured and integrated a Front of Line Robotic De-stack System and an End of Line Stack System for an automotive manufacturing facility.

- Atlas built and installed a complete blank wash system for a manufacturer in China that included a De-Stacker, Blank Washer, and End of Line Stacker with Lift Tables for loading and unloading dies.

ATLAS TECHNOLOGIES

A Division of Stonebridge Technical Enterprises, Ltd.

Copyright © Atlas Technologies. All Rights Reserved.

CORPORATE HEADQUARTERS

14165 Fenton Road, Suite 102C

Fenton, MI 48430, USA

PHONE

810.629.6663