End of Line Stacker Systems

Atlas End of Line Systems are constructed of a modular design, allowing multiple configurations to suit our customers exact needs. Whether you require our End of Line Parts Racking or End of Line Blank Sheet Stacking System, each has been designed to improve production flow rates and eliminate production line interruptions.

MULTI-VAC Stacking System

Atlas Technologies presents a new design that meets the needs of companies who process both steel and aluminum parts for the automotive industry. The stacking unit provides a means for high speed blanking of both steel and aluminum, using a single design that operates under identical parameters. Companies now have the ability to switch production between steel and aluminum quickly and efficiently. The stacking technology continuously feeds the blanks into the stack boxes, no interruptions or changes necessary.

The stacking system will accommodate blank types such as contoured, waffle edge, trapezoids, square and rectangle of varying sizes and weights. The stacker offers four programmable stacking modes that achieve a crisp defined stack of blanks.

This complete stack handling technology can also be retrofitted to existing steel only stack conveyors. Click on the product details tab and download a complete list of benefits and features.

End of Line Blank Stacking System

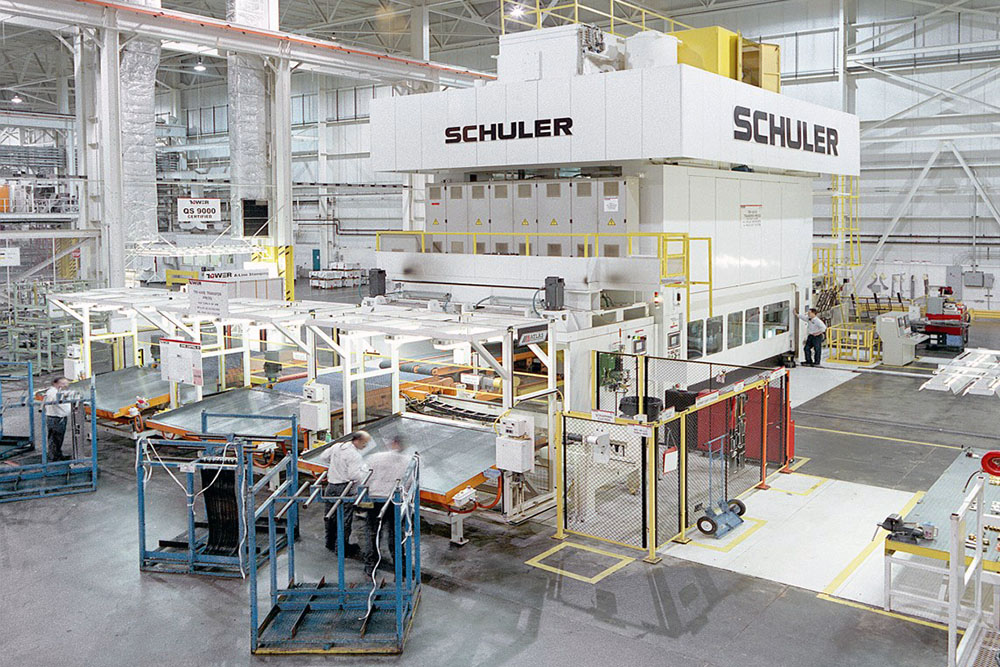

Atlas’ End of Line Blank Stacking System reduces manual handling and improves surface finish quality. Our End of Line Blank Stackers also increase production of cut-to length operations and stacking of sheet metal blanks as they exit the blanking press or trapezoid shear. Our Blank Stackers help prevent marring of the surface finish and the contaminants that are introduced to processing when manual operations are in place. These type of quality improvements are achieved when an Atlas End of Line Blank Stacking System is used for handling pre-painted steel or exposed steel and aluminum.

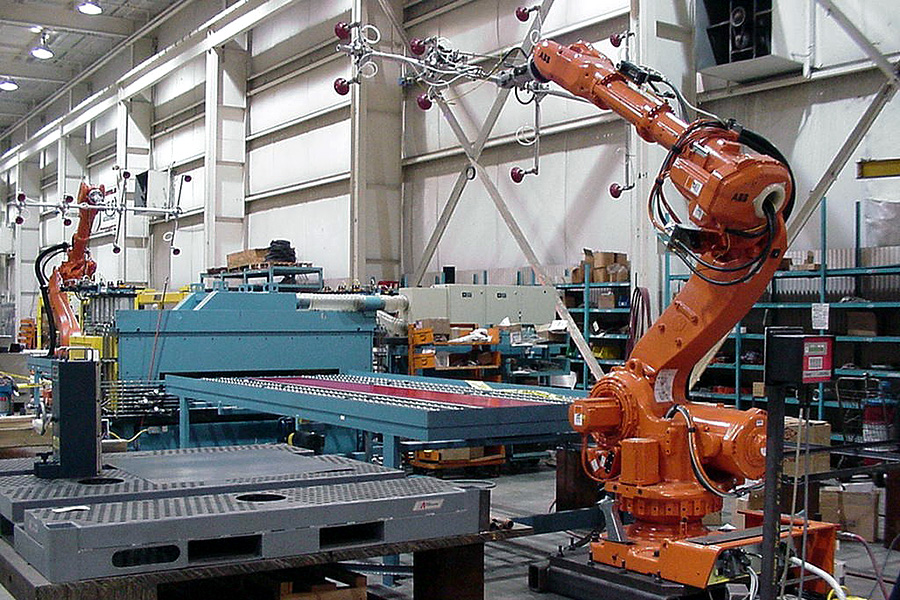

Atlas Blank Stackers can handle rectangular, trapezoid, patterned, contoured or irregular shaped parts. Our End of Line Blank Stacker Systems have proven applications in the automotive, appliance, contract stamping, steel service centers, toll processors and many other metal forming industries. Atlas End of Line Stackers offer robotic, magnetic belt and magnetic roll stackers for ferrous steel blanks, and vacuum-based stackers for non-magnetic aluminum blanks. Systems can be configured to meet desired press speeds and material requirements. Atlas Blank Sheet Stackers can be built as single station or dual station stacker accommodating steel and/or aluminum.

End of Line Part Racking System

End of Line Part Racking Systems are high speed conveyance systems located at the end of a Transfer Press or after the last press in a traditional tandem press line. The system services multiple racking stations simultaneously, delivering parts in close proximity to the associated container. Therefore, optimal production speed and increased production throughput is achieved when incorporating an End of Line Part Racking System.

Atlas’ End of Line Part Racking Systems was developed to improve part flow rates from the press. The End of Line Part Racking design will also improve the flow of any Automated Guided Vehicles and/or fork truck traffic that is associated with delivery and removal of the part racking containers. The End of Line Part Racking System configurations provide a safe zone between the racking personnel and the isle utilized for fork truck traffic. A clear pathway is made for plant traffic allowing for the efficient delivery and removal of parts containers. Ultimately, this system provides a safer operator environment.

ATLAS TECHNOLOGIES

A Division of Stonebridge Technical Enterprises, Ltd.

Copyright © Atlas Technologies. All Rights Reserved.

CORPORATE HEADQUARTERS

14165 Fenton Road, Suite 102C

Fenton, MI 48430, USA

PHONE

810.629.6663

EMAIL

sales@atlastechnologies.com

FAX

810.629.8145