Levels of Tooling Support

The Components Product Group is capable of providing customers with the level of support you choose in your upcoming Finger Tooling programs. To assist our customers in making your choice, we would like to clarify what is included with the various levels of support for implementation of your Finger Tooling Project.

Components Only

- Customers have the ability to design the configuration of the finger tool assembly and select the appropriate components and shovels for their application.

- Customers have the ability to assemble the components for their finger tool assembly to their design.

- Customers are able to provide a list of standard components required via the internet or phone to our Components Product Group.

- A formal quotation and subsequent purchase order acknowledgement is submitted to the customer.

- Orders of standard components are typically shipped within two days.

- Overnight shipment is available for in stock items.

Finger Tooling Design

- Atlas tooling engineers review customers die data to determine the proper method and location for the finger tool to capture the part for all die stations.

- If proper finger clearances have not been allowed for in the die design, our tooling engineer will inform the customer.

- Engineering package includes the general arrangement drawing of the press, dies, process parts, transfer and tooling rails, and finger tooling assemblies.

- Included with this service is a three dimensional assembly drawing of each finger tool assembly defining set-up dimensions and angles, as well as, the identification of components and bill of material.

- Detailed drawings are provided for all custom designed components.

Die Integration Services

- Atlas tooling engineers are a consultant to the customer working with the die designer during the die design phase.

- Objectives are to assist the die designer with recommendations for clearances in tool steel to accommodate adequate capture of the part for the transfer motion.

- Additional recommendations are made to minimize the clamp, lift and transfer stroke of the transfer by reviewing location and sizes of obstacles such as die posts, heel blocks, cams, etc.

- The primary objective is to assure that the die design is transfer friendly and able to optimize the transfer and part path for the greatest throughput possible.

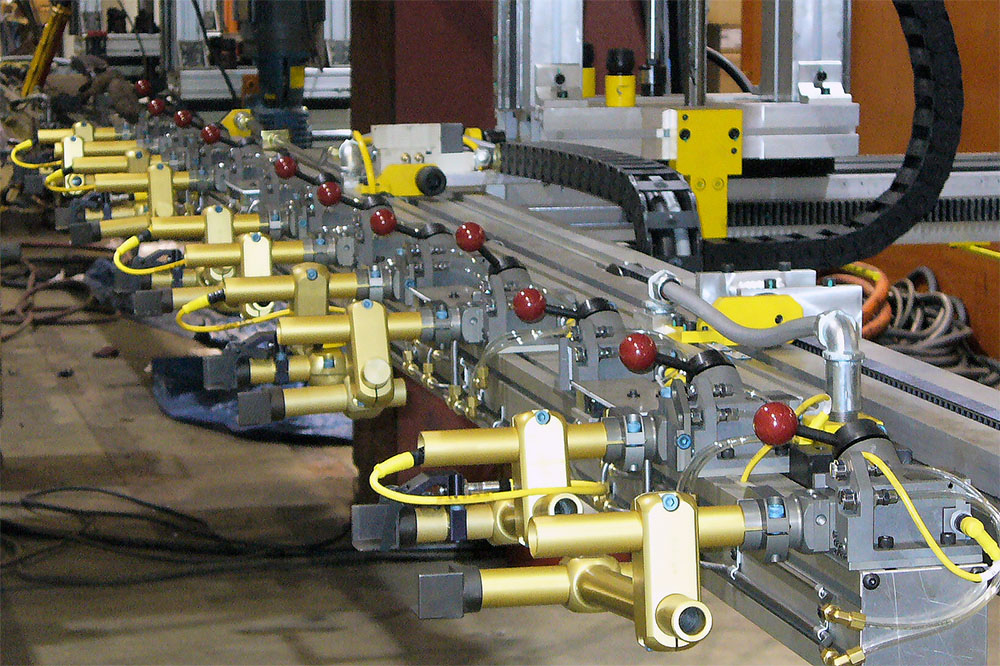

Finger Tooling Assembly

- Atlas manufacturing will assemble the components into finger tooling assemblies to the Atlas or customer supplied design.

Start-up Assistance

- Atlas service technicians will assist the customer in the physical set-up and final adjustment of the finger tooling assemblies to the dies and process parts.

- If the customer is using an Atlas FLEX Tri-Axis Servo driven transfer, the service technician will assist in programming and optimizing the transfer and part path.

ATLAS TECHNOLOGIES

A Division of Stonebridge Technical Enterprises, Ltd.

Copyright © Atlas Technologies. All Rights Reserved.

CORPORATE HEADQUARTERS

14165 Fenton Road, Suite 102C

Fenton, MI 48430, USA

PHONE

810.629.6663

EMAIL

sales@atlastechnologies.com

FAX

810.629.8145